GE Yaw Brake Upgrade

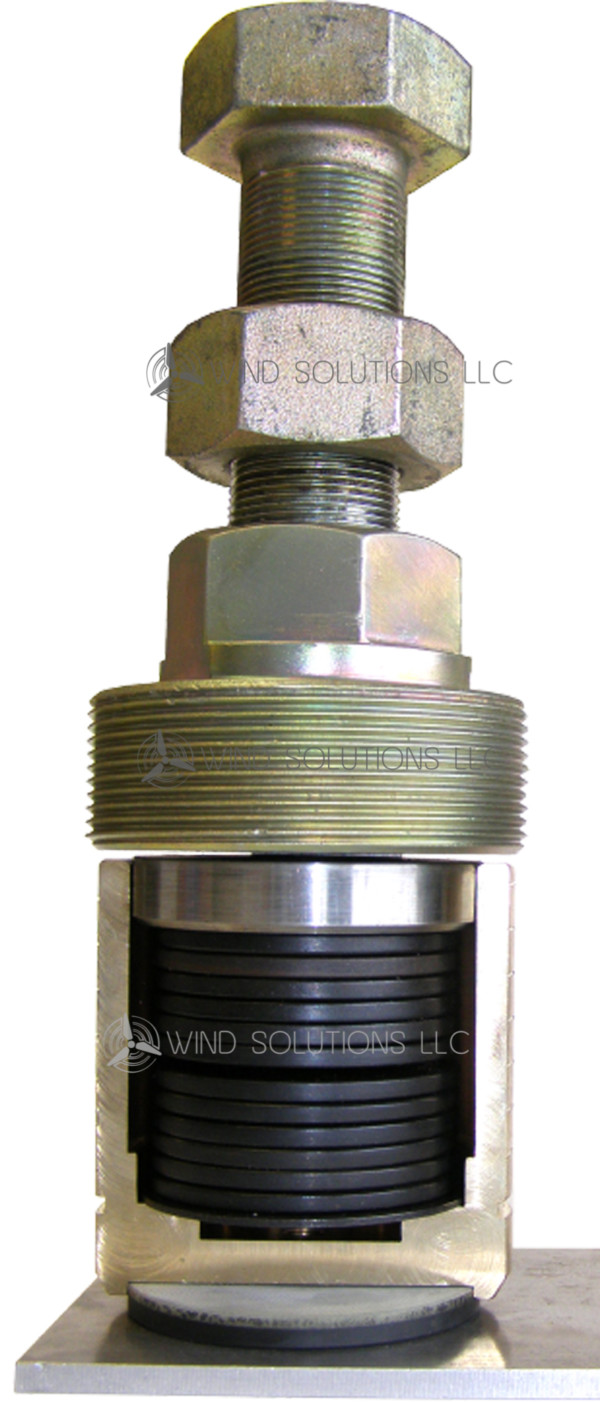

Original Design

Problem: Noise (Fog horning) and the High Cost to Maintain Yaw Brakes

High variability in torque values lead to uneven loading on brake pads causing vibration (fog horning). And piston/stem interface cause premature component failures.

Wind Solution Design

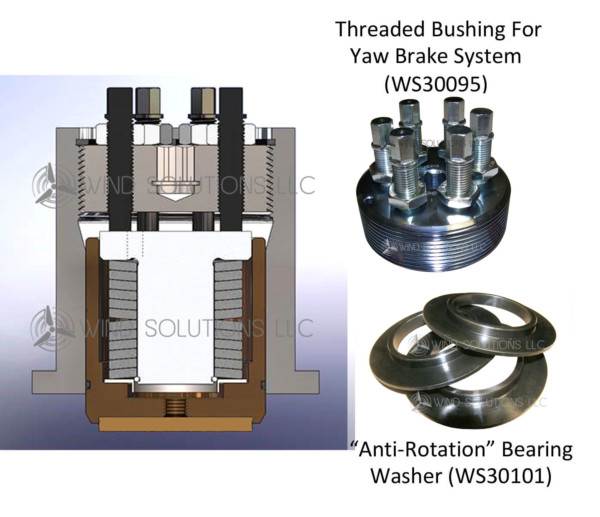

Solution: Wind Solutions Threaded Bushing with Anti-rotation Washer

The threaded bushing design improves preload accuracy and system reliability; and eliminating noise issues. It also reduces component failures and improve safety by reducing safety issues with high torque equipment.

GE Yaw Brake Upgrade

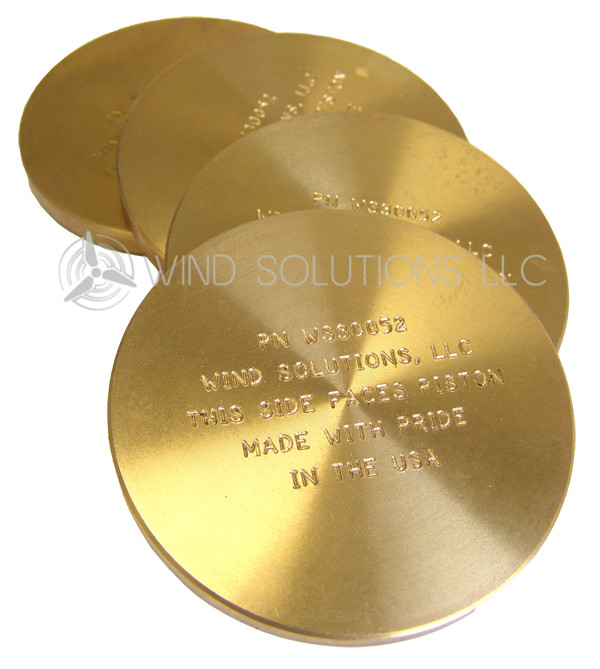

Next Generation Piston Design

- New Pad Diameter- 94mm

- Removal of counter bore gains 3mm of wear material

- Upgrade pad material since no edge loading

- Puck permanently affixed to piston

- 94mm Piston w/ Extended 9mm Pad (WS30129G001)

Additional Component Manufacturing

Piston (WS30082)

Threaded Bushing (WS30057)

Adjusting Screw (WS30059)

Stem (WS30060)

Spring Washers (WS30053)

Sintered Bronze Pad (WS30052)